Colonna’s Shipyard: Forged in Steel, Anchored in Legacy

Colonna’s Shipyard is a fifth-generation, family-owned medium-sized shipbuilder, led by Randall Crutchfield, Chairman & CEO, today. Founded in 1875 by 26-year-old ship carpenter Charles J. Colonna with a $2,000 loan from his brother, he founded a company that has not only withstood the test of time, but today stands ready as a multi-faceted ‘blue collar industrial complex’ to help in the effort to effectively rebuild the U.S. shipbuilding base, and more specifically to help rebuild the U.S. Navy and U.S. government-owned fleet of ships.

In an industry where tradition meets transformation, Colonna’s Shipyard stands out. This year, the company celebrates its milestone anniversary, 15 decades of highs and lows, earmarked with the multitude of people and signature projects that have helped to define this journey, the shipyard and it’s growing stable of blue-collar sister companies a testament to perseverance.

To put it in perspective, Colonna’s Shipyard was in business before the invention of the phonograph, the Incandescent lightbulb, the automobile & the airplane … Colonna’s Shipyard was formed just 10 years following the U.S. Civil war; Ulysses S. Grant was president, and since then there have been 27 additional U.S. presidents.

It’s timely tale, too, as shipbuilding and a resurgence of U.S. industrial might in the maritime sector is at the forefront of political agenda.

At the helm today is Randall Crutchfield, a fifth-generation descendant of founder Charles Colonna. Crutchfield, now chairman and CEO. His personal journey through nearly every layer of the organization mirrors the evolution of the company itself—from humble, horse-powered beginnings to a modern, multi-division enterprise serving both commercial and government customers with precision and scale.

From building wooden ships to building sections for the U.S. Navy’s Columbia Class submarines, Colonna’s Shipyard’s breadth and diversity is its strength. Image Courtesy Colonna’s Shipyard

From building wooden ships to building sections for the U.S. Navy’s Columbia Class submarines, Colonna’s Shipyard’s breadth and diversity is its strength. Image Courtesy Colonna’s Shipyard

Crutchfield’s Journey: From the Docks to the Boardroom

For Crutchfield, Colonna’s has never been just a business: it is family. As the son of a Colonna (his mother), he grew up amid the dust, grit and iron of the shipyard. “While other kids were on spring break, I was out here on the waterfront,” he said.

While Crutchfield admits that at the time “I didn’t have very much appreciation for doing that,” he admits that those summers spent building ship blocks and learning trades from multi-generational workers would later serve as the foundation for a leadership philosophy rooted in respect for hands-on work and institutional memory. “A lot of those guys that I was working with side-by-side still work here today.”

After earning his degree, Crutchfield returned to the yard with a long-term commitment to his family’s legacy. His first major assignment was spearheading a land development project that would redefine the yard’s capabilities. The centerpiece? A then-record-setting 1,000-metric-ton Marine Travelift, transforming underutilized acreage into a bustling 12-slot service center for tugboats, fishing vessels, Coast Guard cutters, and Navy support craft.

“The lift changed everything,” Crutchfield explained. “Instead of hauling out one or two vessels at a time, we could now work on a dozen—simultaneously.” It was a bold move that signaled Colonna’s appetite for reinvestment and scale.

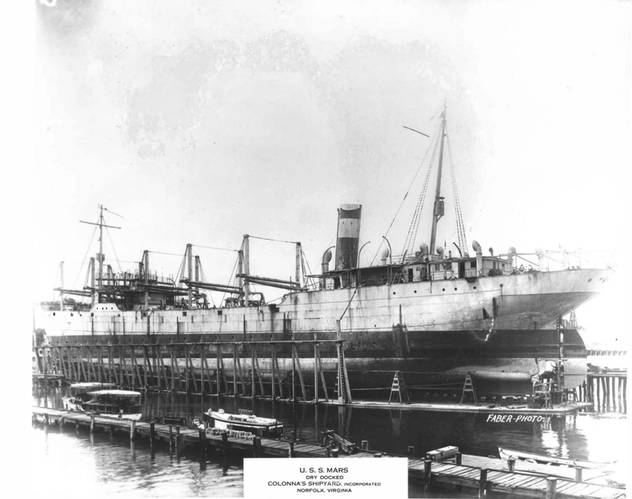

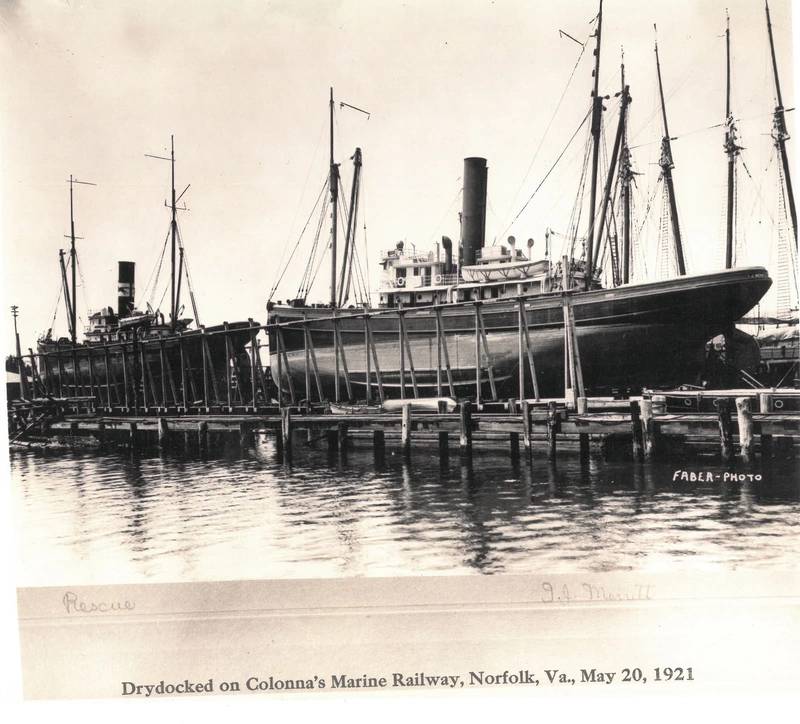

Railway #3 Installed was installed in 1890, and it's still in service today, continuing to serve the regional commercial maritime market including barges and fishing vessels. Image courtesy Colonna's Shipyard

Railway #3 Installed was installed in 1890, and it's still in service today, continuing to serve the regional commercial maritime market including barges and fishing vessels. Image courtesy Colonna's Shipyard

From Railways to Dry Docks: “A two horsepower business”

Colonna’s origins date back to 1875, when Charles Colonna secured a $2,000 loan—twice—from his brother.

“We started out with a horse-drawn marine railway,” said Crutchfield. “Think about that, think about where we are today. Think about a horse walking in a circle around a king post hauling a ship out of the water. If the ship was heavy, two horses were needed, so we make the joke that we were two horsepower business when we first started out. I’m just trying to contextualize the beginnings of the place.”

That original railway – built in 1890 – remarkably is still in operation 135 years later, and booked nearly 300 days a year, a living monument to durability and tradition.

When asked to discuss the shipyard’s pivotal moments over 15 decades, Crutchfield was eager to share a select few of the shipyard’s failures, instead. “I think that those low points, and our willingness to get through them, is what ends up being the highlight reel.

One was a large capital outlay during World War One to install another marine railway at the request of the DoD to help the war effort. But by the time the railway was built, the war was over and the business nearly went bust. “We got really tight, but I’ll tell you that that marine railway stayed in operation for close to 100 years. If you can look at it from a long-term perspective, you can just dig through the hard times, do the right thing, and believe it’s going to pay off eventually.”

Another rough patch during his grandfather’s tenure was when the shipyard purchased a 14,000-ton drydock from the Dutch government to help execute a multi-hull, large ship conversion contract from the U.S. Coast Guard. “Midway through that contract was terminated, and we ended up in a really poor cash flow position. We were overextended and we had to file Chapter 11, eventually reorganizing.”

Each challenge, he says, became a crucible from which the company emerged stronger, more resilient, and more committed to its mission.

“My grandfather once got a meeting with the Secretary of the Navy during a time of severe financial strain,” Crutchfield recounted. “Turns out, the secretary’s grandmother lived a block from our gate. Whether that swayed the decision or not, we got a settlement that helped us survive. Those are the moments that define a company.”

“Watching our people polish every weld, track every joint, compile the mountain of paperwork, and ship the component to the nuclear builder: just incredible. It’s the kind of work that energizes a team.”

“Watching our people polish every weld, track every joint, compile the mountain of paperwork, and ship the component to the nuclear builder: just incredible. It’s the kind of work that energizes a team.”

– Randall Crutchfield, Chairman & CEO, Colonna’s Shipyard, in discussing the shipyard’s role in the Columbia-class submarine program.

Facilities and Technology

Today, Colonna’s spans 120 acres of prime waterfront in Norfolk, boasting 11 piers, three floating dry docks (up to 14,000 tons), and that still-active 1890 marine railway. But it’s the technological diversification that distinguishes Colonna’s from many peers.

Beyond traditional ship repair, the company has grown into a vertically integrated industrial ecosystem through its sub-brands. Steel America, for example, specializes in large modular fabrication and heavy machining, producing components weighing up to 1,000 metric tons. Steel America’s capability to manufacture and barge out massive bridge sections, hydro gates, and submarine modules has opened new revenue streams and strategic partnerships with defense primes and energy customers.

Its machine shop, bolstered by Navy and Coast Guard contracts, handles shaft and rudder work, both in-shop and through in-place machining. Weld America, launched in 2020, offers turnkey specialty welding solutions. And in 2023, Colonna’s acquired Acurity Industrial Contractors in Owensboro, Kentucky, expanding into power generation, process piping, and distillery infrastructure. “It’s still blue-collar project work, just in another sector,” said Crutchfield.

In San Diego, Colonna’s West mirrors the Downriver business unit in Norfolk, providing mobile ship repair services at Navy bases and commercial yards. This national footprint positions the company for maximum flexibility while supporting Navy readiness and fleet sustainment.

From building wooden ships to building sections for the U.S. Navy’s Columbia Class submarines, Colonna’s Shipyard’s breadth and diversity is its strength. Image Courtesy Colonna’s Shipyard

From building wooden ships to building sections for the U.S. Navy’s Columbia Class submarines, Colonna’s Shipyard’s breadth and diversity is its strength. Image Courtesy Colonna’s Shipyard

Projects

Two projects stand out in Crutchfield’s tenure as signature moments. First, a full-year overhaul of a Navy Landing Ship Dock (LSD) alongside a local partner. The project tested Colonna’s ability to perform high-complexity work traditionally reserved for larger, prime contractors. “We surprised some folks,” Crutchfield admitted. “And we proved to ourselves that we could compete and deliver.”

The second was Colonna’s role in the Columbia-class submarine program—building high-spec, technically rigorous structures at the front end of the Navy’s most sensitive projects. “Watching our people polish every weld, track every joint, compile the mountain of paperwork, and ship the component to the nuclear builder: just incredible,” said Crutchfield. “It’s the kind of work that energizes a team.”

When it comes to shipyard workforce, ‘the next generation’ is a perpetual challenge. According to Crutchfield, another challenge is effectively managing the recruitment and workforce that varies widely in age. Image courtesy Colonna’s Shipyard

When it comes to shipyard workforce, ‘the next generation’ is a perpetual challenge. According to Crutchfield, another challenge is effectively managing the recruitment and workforce that varies widely in age. Image courtesy Colonna’s Shipyard

Looking Ahead: Government Work Rises, Workforce Evolves

While Colonna’s historically split its business 60/40 in favor of commercial work, the pendulum has swung. Today, the mix is roughly 60% government, 40% commercial, a shift driven by expanded fabrication work for the Navy and growth in surface fleet maintenance. The shop floor today hums with components for aircraft carriers, submarine modules, Army and Coast Guard vessels, and NOAA ships, alongside commercial tugs, barges, and fishing boats. Colonna’s isn’t just riding the wave of maritime reindustrialization, it’s building it.

But growth presents challenges.

The company currently employs about 750 people, and Crutchfield acknowledges the complexities of managing a workforce that spans five generations. “We’re hiring baby boomers through Gen Z,” he said. “Each group has different priorities, and we need to address all of them—from pay and benefits to workplace culture.”

Recruitment is a long game, Crutchfield noted, and it hinges on storytelling. “Let us tell you what it’s like to build something that serves the country or moves a thousand tons downriver. This work has meaning.”

2015 – Colonna’s Shipyard West was founded, expanding the enterprise to San Diego, CA.

2015 – Colonna’s Shipyard West was founded, expanding the enterprise to San Diego, CA.

U.S. Shipbuilding: A Call to Action

Crutchfield is clear-eyed about the broader implications of Colonna’s journey. “This is the most exciting time in my career to be in the maritime industry,” he said. With bipartisan support for maritime revitalization and strategic legislation like the proposed Ships for America Act, the sector is poised for a generational reset.

But he also offers a caution: “We’re late to realize what other countries already knew: China, South Korea, Turkey, Japan. They invested intentionally in their shipbuilding capabilities. We’re only now catching up.”

Colonna’s is moving ahead with or without federal incentives, investing in dry docks, machining, and fabrication capabilities. “We’re ready to compete—fair and square,” Crutchfield said. “But the country has to decide if shipbuilding is a priority again.”

After 150 years, Colonna’s is not standing still. The company that began with a $2,000 loan and a horse-powered railway now shapes the steel that powers America’s future, both for commercial endeavors as well as military might. Randall Crutchfield, carrying both a legacy and a vision, is steering the company toward a new era defined by strategic relevance, multi-sector capability, and an unshakeable commitment to American maritime excellence. “The people who work here breathe this stuff,” he said. “We’re builders, fixers, problem-solvers. And after 150 years, we’re just getting started.”

Colonna’s Shipyard “By the Numbers”

Piers | 11

Acres | 120

Water Depth | 30 ft.

Drydocks | 3 [14,000, 12,000 & 2,400 tons]

Travelift | One 1,000-ton

Marine Railway | 1 [built in 1890]

Workforce | 400-500

Colonna’s Shipyard Divisions & Affiliates

- Colonna Down River Division

- Accurity Industrial Contractors

- Norfolk Barge Company

- Steel America

- Weld America

- Colonna’s Shipyard West

Watch the full interview with Randall Crutchfield on Maritime Matters: The MarineLink Podcast, here: